The Ontario was a Barque rigged steamer. The definition of Barque rigged is a vessel that has three or more masts. The foremasts are square rigged and the aftermast is rigged fore and aft as in the image to the left.

.

SS ONTARIO

RESEARCHED AND WRITTEN BY PAUL HENNESSEY (NORFOLK WRECK RESEARCH)

Position ... Withheld (Haisborough Sands)

Type ... Barque rigged Steamer / passenger / cargo / three masts

Accommodation for 70 first class and 800 between deck passengers. Crew of 80 approx

Built ... 1864 / launched 3rd September 1864 / completed October 1864

Construction ... Iron

Dimensions ... Length 385 feet , beam 41 feet, hold depth 28 feet

Tonnage ... 3325grt

Builder ... Palmer Brothers & Co of Jarrow

Engine builder ... Palmer Brothers & Co of Jarrow

Engine type ... Please read below, identification of engine type (NWR)

Owner at time of loss ... National Steam Navigation Company, Liverpool

Official number ... 50491

Port of registration ... Liverpool

Cargo ... 1933 tons of coal, Iron & cast goods

Lost ... 16th October 1864 on maiden voyage (Shields to Alexandria)

Cause of loss ... Grounded on Haisborough Sands

Casualties ... None

Discovery and identification of the Ontario.

The Ontario was located in 2022 by local diver Neil Hooper. Identification of the site was made by the recovery of the ships bell by Neil.

Below Left ... The Ontario's bell and hanger awaiting cleaning (Image courtesy of Neil Hooper)

Below right ... The bell and hanger during the cleaning process (Image courtesy of Neil Hooper)

.

.

Below ... Water feed tank for the boiler. Image courtesy of Stan Moore

Identification of engine type. Paul Hennessey (Norfolk Wreck Research, June 2025)

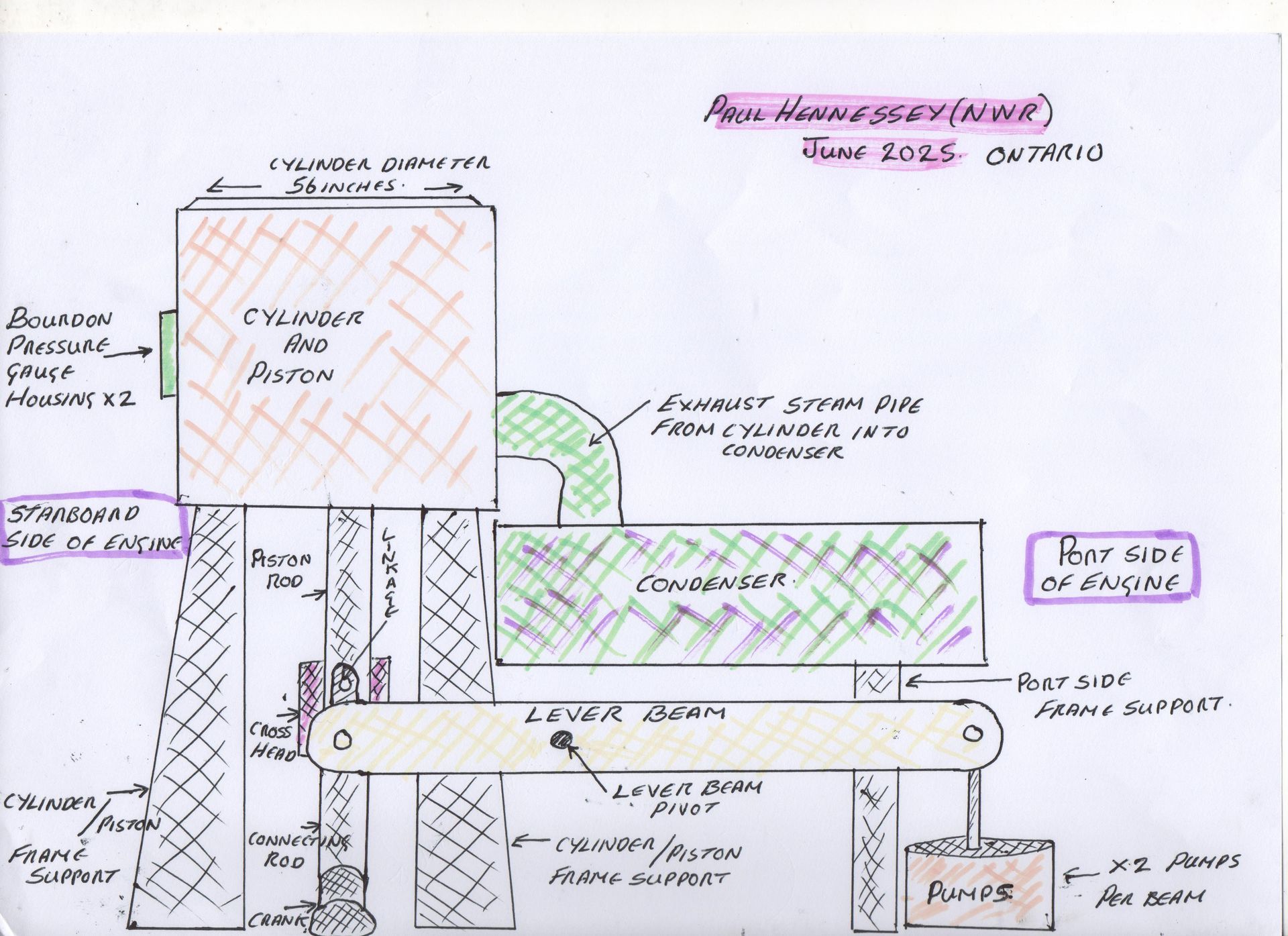

There appears to be no information available regarding the type of machinery the Ontario was fitted out with at the time of her build. After several dives on the site it can now be confirmed that the engine is of a twin cylinder, none compounding, direct acting, inverted vertical design. One of the cylinder covers is missing, forward cylinder, starboard side of engine, this has in turn allowed for an accurate measurement of the cylinder to be taken, this being a diameter of 56 inches. Within the cylinder at the top can be seen the steam inlet port and exhaust port. As stated this is a none compounding engine, ie only one phase of expansion takes place, in turn both cylinders are of the same size, ie 56 inches in diameter. On each side of the engine can be found a horizontal lever beam, this running the entire length of the engine. Communication in order to facilitate the rise and fall of the lever beam on its point of pivot is made via the cross head, plus various linkage. The purpose of the lever beam is to run four pumps that are situated at the port side of the engine. Two pumps per beam.

Boiler ... Box type

Definitions

Twin cylinders ... Two cylinders of the same size, ie diameter

None compounding ... Only one phase of expansion in the engine takes place.

Direct acting ... Direct communication of the engines crank to the screws drive shaft, ie no spur wheel. A spur wheel, also known as a spur gear, is a type of gear characterized by its straight, radially projecting teeth on a cylindrical or disk-shaped body. These gears are commonly used to transmit rotational motion between parallel shafts.

Vertical / inverted ... The cylinders are situated directly in line above the crank (vertically)

Cross head ... The linkage between the piston rod and connection rod that facilitates the free movement (pivot) of the connecting rod back and forth as the piston goes up and down, this in turn acting upon the crank shafting via the crank arms and pin. This simple but highly effective piece of engineering design is what turns the reciprocating movement of the cylinders, ie back and forth into the rotational movement of the prop shaft, and in turn the screw.

Below ... Sketch showing the basic layout and workings of the forward side of engine

Below ... Sketch showing the basic general layout and workings from an aerial view

Below ... Diver alongside the engine (Courtesy of Sam Lister)

Below ... Two of the engine's port side pumps. Note the linkage to the leaver beam in order to work the two pumps. ( Image Courtesy of Sam Lister)

Below ... What now remains of the two Bourdon pressure gauges and associated pipework. Upper starboard side of engine. The Bourdon pressure gauge was patented in 1849 by the French engineer Eugene Bourdon.

For more information click on the link below.

Below .... A piece of broken crockery, possibly a tea cup? Upon it is the Ontario's owners crest (National Steam Navigation Company Limited) Recovered and reported to the ROW in June 2025 (Paul Hennessey)

National Steam Navigation Company Ltd (Owners of the Ontario)

Founded in Liverpool in 1863 with the intention of running from Liverpool to the US (south). However due to the civil war, routes were set up to New York. In 1870 the company added London - New York . They later ran ships from London to New York on a fortnightly basis. In 1884, the companies ship America made the voyage in 6 days, 14 hours, 18 minutes. Apart from one sailing in 1894, the passenger service to New York was discontinued in 1892. The company was taken over by the Atlantic Transport Line and ran freight services only. The National line went into voluntary liquidation in 1914.

Below ... Lower dead eye recovered from the Ontario by Nick Schiller. Recovered and reported to the ROW June 2025.

For a very interesting detailed account of the deadeyes recovered from the Ontario by Nick follow the link below.

Below ... An article featured in the Newcastle Courant on the 9th September 1864 reporting on the launch of the Ontario.

Below ... Steam winch (Courtesy of Stan Moore)

Below ... Anchor (Image courtesy of Stan Moore)

The anchor pictured below is similar in design to that of a Trotman anchor, ie the horns protruding on either side of the arms just below the fluke on either side. The Shank of the anchor was found to be lying on the seabed next to the section pictured below. The anchor when in use would have the shank bolted (single bolt) through the crown, ie the lower section of the curve on the arms as pictured below. This in turn would allow the shank and arms a point of pivot which allowed them to swivel so as when one arm was dug in to the seabed the other pressed hard on the shank. The horns on the outside of the arms when in the seabed in theory gave a more positive hold than an anchor of conventional design.

Below ... Trotman anchor at work.

Cause of loss

The Ontario left the Tyne dock on the 15th October 1864 at 3pm under the charge of her pilot Alexander Scott, who in turn was to remain with the vessel until she reached Dover. A course of SSE was steered until 9pm, at this point the Whitby light was seen some seven miles off. Her course was then altered to south east, this continuing until 5.30am on the 16th October. At this point the Dudgeon and Dowsing light should have been in view. With neither the Didgeon or Dowsing lights in sight the pilot thinking he was outside the Dowsing Sand hauled the Ontario to the west with the intention of passing through the Wold and Haisborough Gat. At 9.12am the Haisborough church was sighted some ten miles off to the WSW. With this the pilot put the helm to starboard and stopped the engine. Despite the actions of the pilot the Ontario found herselfaground on Haisborough Sands where she in turn became a total loss. At the enquiry the captain (Brooklin) was found to hold no blame for the Ontario's loss as the pilot had been in charge of the vessel.The pilot in his own defence attributed the loss to that of a faulty ships compass.

Extract from the Norfolk Chronicle

A new screw steamer, the Ontario of 3,200 tons upon her first voyage, from Shields to Alexandria, laden with coals and iron, struck upon Happisburgh Sand. Three steam tugs and the Caister lifeboat proceeded to her assistance, and her cargo was thrown overboard, but every effort made to get her off proved unavailing. On the 17th the weather became very threatening, and the lifeboat took off 56 coal heavers, but the captain and officers and 86 crew determined to remain with the vessel. During the night the storm increased, and the crew, apparently in great distress, sent up rockets and burned blue lights. The Yarmouth lifeboatmen were implored by the ships agent, Mr Butler, to go to the ship, but in vain. They refused to launch the lifeboat unless they were paid from £400 to £500, saying that the steam tugs had begun the work and had better finish it. The Caister lifeboat stood by the vessel, which, by the 20th, had so settled down that it was hopeless to attempt to get her off. On this day 68 of the crew left in a lifeboat belonging to the steamer, but the captain and officers declined to desert her. They were, however, compelled to leave on the 22nd, when she became a total wreck, and was offered for sale. The original value of the Ontario was £120, 000.

Below ... An article featured in the Newcastle Journal on the 21st October 1864 reporting on the loss of the Ontario.

The Ontario today (2025).

The Ontario makes for one of the most spectacular dives off the Norfolk coast, and in a depth range of 13 - 20mtrs there is plenty of bottom time to truly appreciate this stunning wreck. There are large sections of the Ontario that are still pretty much in tact, the main part being the magnificent stern section. Throughout the site can be found various fittings from the rigging, ie deadeyes and pulley blocks. Other items of interest include steam winches, a water feed tank for the boiler, spare crank, masts and anchors.. All in all the Ontario makes for a very memorable dive.